Performance Drilling

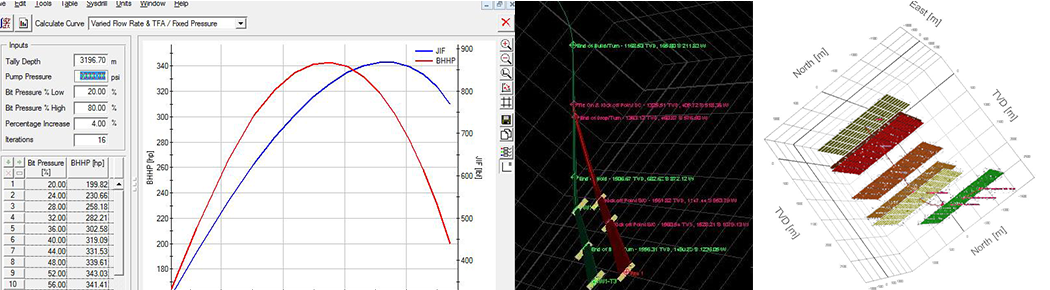

EDS is also used Drilling motors to provide superior performance when drilling vertical holes in rotary drilling mode or over extended vertical drilling intervalsin deviated holes. The term “performance drilling” has been developed to describe drilling using a stabilized motor with a bottom hole assembly (BHA) configured for stabilizers similar to rotary drilling for deviation control. When drilling conditions require, the rotary can be engaged to increase bit speed to optimize performance.

With a drilling motor in the BHA, the rotary table and drill string can be rotated at a more moderate pace while still obtaining a superior rate of penetration(ROP) through the additional rotation provided to the bit by the drilling motor. The ability to operate at a reduced drill string rotary RPM reduces wear on casing and wear and fatigue of the drill string and rotating top side components.

By turning the bit several times faster than the drill string, drilling motors provide increased angle control under the adverse conditions found in many vertical applications. This provides more effective control over deviation and doglegs. Drilling with a motor can also be more fuel efficient than straightrotary drilling as the hydraulic power required driving the motor, and drill bit may be less than the mechanical power required to rotate the drill string, with its associated friction losses.

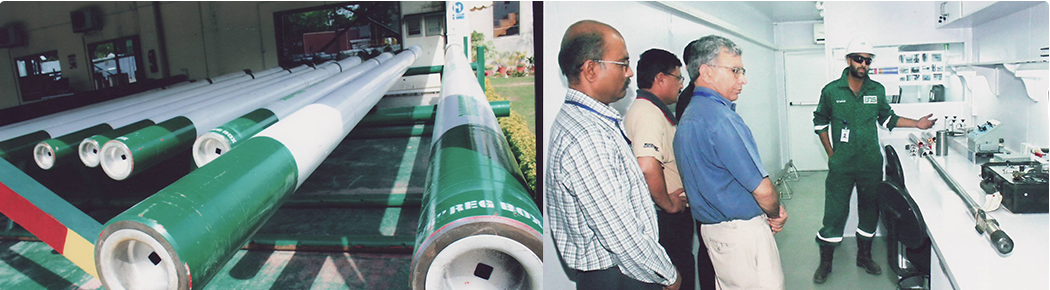

The proven reliability of EDS motors along with the wide range of available power sections make them well suited for performance or extended interval drilling in both vertical and deviated wells.

Compared to rotary drilling technology, drilling motors offer intangible benefits that should be taken into consideration in the final cost to benefit analysis. Such benefits include:

- Fewer round trips for BHA changes.

- Minimized wear, tear and fatigue of drill string components, surface pipe and casing, resulting from reduced drill string RPM.

- Fewer hole problems, such as formation swelling, formation caving, doglegs, keyseats and hole sloughing, resulting from higher ROP and less open hole time.

- Reduced drill string torque.

- Faster and smoother casing setting

EDS Solutions

Our Customer